About Us

Rowing in your direction

Every day we row in your direction. Whatever your liquid pharmaceutical product is, our ability to build the machines to make it is absolutely certain.

Our Mission

Satisfying your user requirements

BRAM-COR aims to provide the highest pharmaceutical quality, a convenient quality/price ratio and wide customisation for every single plant. All Pharmaceutical Facilities need to be up-dated, competitive and efficient, to diversify production programs, to reduce life-cycle costs and, above all, to comply with the appropriate pharmaceutical GMP regulation. BRAM-COR project drivers are aimed at satisfying the latest pharmaceutical requirements, aligning the final product to the international pharmacopoeias and capitalizing upon a careful, customer-oriented project management.

Equipment and process flow are designed to avoid mix-ups of components, drug products, capping and labelling and overcoming in-process risks and cross contamination; this is achieved through the development of:

- Conceptual Design describing the general project organization

- Detailed Engineering Plans, considering all process flows (raw materials, finished products, personnel, waste, etc.) and detailed project specifications.

BRAM-COR additionally ensures a qualified and professional customer support throughout the entire life cycle of our pharmaceutical plants, on account of our rigorous teamwork etiquette. The majority of our business concerns long-term clients. A close partnership with our Customer is therefore the core of our work etiquette. The direct contact with the End User ensures full commitment to long term relationships.

Our Vision

Experience and passion in processing systems

QUALITY AND PROFESSIONALISM

BRAM-COR’s experience and passion for the processing of stainless steel ensures quality and professionalism even for the smallest details. Energy saving concerns, sanitary quality and certifications for all materials and components and long-term reliability are imperative attributes for all our equipment.

CERTIFIED GOVERNANCE

BRAM-COR products’ quality is ensured by our compliance with the ISO 9001:2015. Planning, monitoring, testing, identifying and recording every step throughout the life of our plants and products constitutes the baseline of our work, from system design to system validation. Continuous improvement is pursued through a scrupulous and dynamic assessment of any non-conformity, owning to the steady revision of our working procedures. For this very reason, each BRAM-COR plant is unique and retains a set of peculiar characteristics.

Ethics & ESG Target

Our leading principles

WE CARE OUR BEHAVIOUR

BRAM-COR’s main activities focus on designing, manufacturing, commissioning, start-up and post-sales services of water treatment equipment, processing systems and filling systems and plants for the international pharmaceutical market. Considering the critical impact of BRAM-COR plants on the of final pharmaceutical products, every employee and director of the Company is required to fully acknowledge and respect BRAM-COR’s established rules and approval procedures for the job management.

ENVIRONMENTAL, SOCIAL AND GOVERNANCE

The Quality Assurance System and any other code of conduct adopted by BRAM-COR are applied to the whole organization and its primary and supporting processes, including the outsourced processes. It is the policy of our company to:

- Comply with all regulations and laws governing every BRAM-COR activity

- Promote correct and appropriate business relations

- Promote health, safety & environment awareness

- Hold all employees accountable for their individual responsibility, ensuring appropriate training

- Assess all process-related risk

- Apply corrective actions to promote continuous improvement.

Our Quality Control

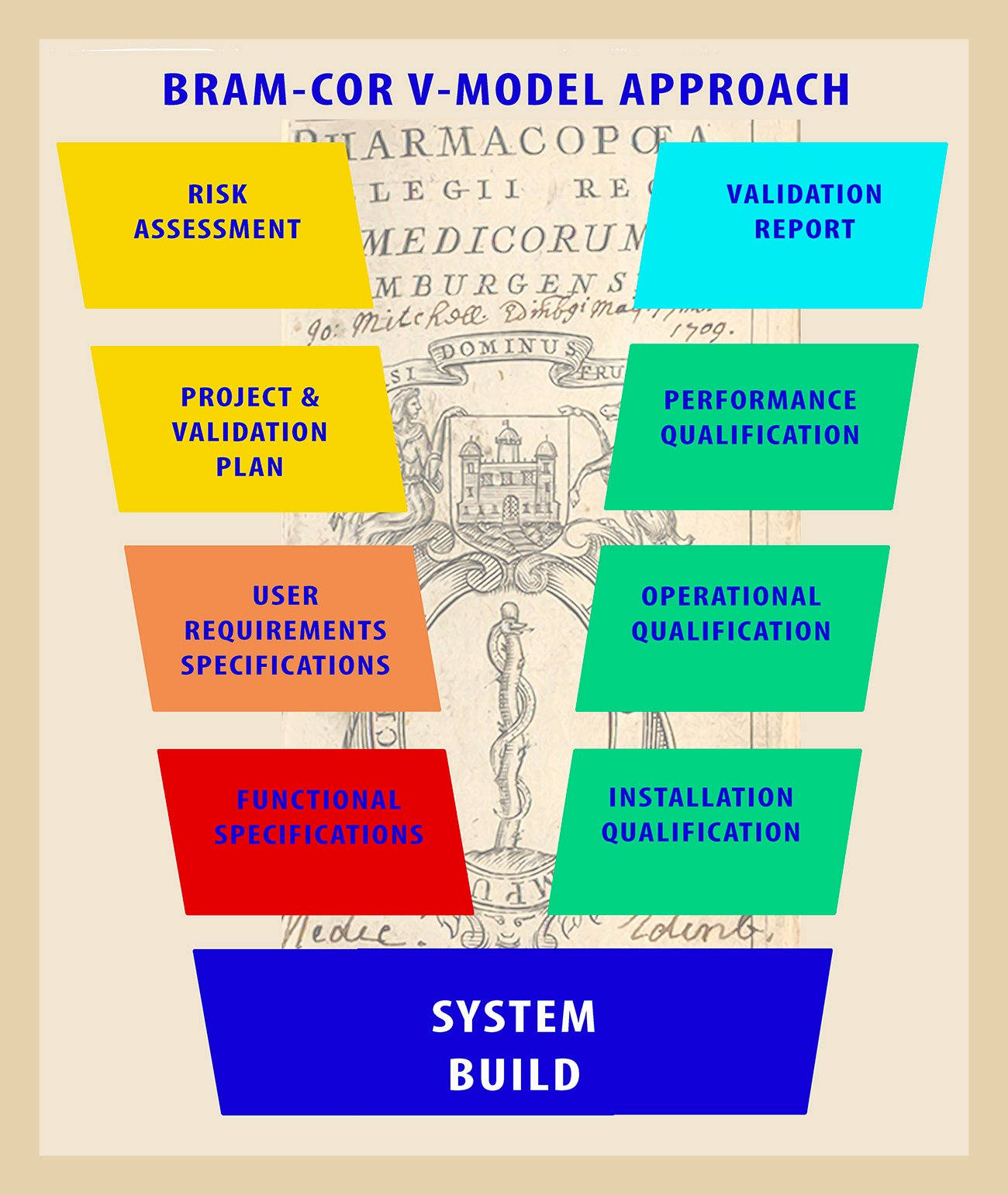

Up-to-date with GAMP 5 V-model

TOTAL VALIDATION

By adhering to GAMP 5, BRAM-COR ensures the proper validation and control of each automated system, resulting in a significant reduction in the risk of errors and ensuring compliance with regulatory standards. The concept consists of a preliminary evaluation to assess the the adaptability of the automated solution to a business process, considers cost-benefit analyses, and develops requirements and potential solutions. After this step, the project includes all aspects of system development and implementation, with planning, supplier assessment and selection, levels of configuration and verification.

LIFE-CYCLE CONTROL

Our cGMP construction

Continuous and strict procedures

IN THE KINGDOM OF STAINLESS STEEL

Each and every BRAM-COR plant and production line is designed and produced rigorously following cGMP procedures. AISI 316L stainless steel pipes and AISI 304 stainless steel frames are welded by qualified welders following BRAM-COR Sanitary Piping procedures.

WIDE-RANGING KNOWLEDGE

Our extended knowledge of raw materials and our strict manufacturing and assembly guidelines, enable BRAM-COR to supervise and qualify every aspect of the plants. Non-destructive tests are performed throughout the entire construction process.