All Equipments

Pharmaceutical Processing Equipment

Reliable Solutions for Sterile Liquid Drug Manufacturing

At BRAM-COR, we design and manufacture advanced pharmaceutical equipment specifically for the production of sterile liquid drugs.

With nearly 50 years of international expertise, we bring deep industry knowledge, precision engineering, and a commitment to

100% Made in Italy quality to every project we deliver.

Our solutions are built to meet the highest industry standards, following cGMP guidelines and supporting full lifecycle compliance.

From initial analysis and risk assessment to system design, validation, and long-term maintenance, every detail is carefully planned to ensure

consistent performance, safety, and efficiency in pharmaceutical production.

Expertly Engineered with Precision

Our deep understanding of pharmaceutical processes allows us to design systems that ensure product quality and regulatory compliance. Each project begins with a detailed analysis of the production needs and includes:

- $Thorough risk assessments

- $Monitoring of all critical quality parameters

- $Full alignment with cGMP (Current Good Manufacturing Practices)

Why Choose BRAM-COR?

Compliant and Quality-Driven Solutions

Advanced Technology and Engineering

Trusted Worldwide, Backed by Experience

Explore Our Equipments

Explore BRAM-COR’s specialized pharmaceutical equipment, designed to meet the highest standards in sterile processing, water treatment, and packaging systems.

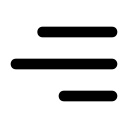

Water Treatment Systems & Lines

✔️ PW – Purified Water

✔️ WFI – Water for Injection

✔️ PS – Pure Steam

Our solutions cover every stage from supply water to final output, with advanced monitoring, material compliance (AISI 316L), certified gaskets, and automated SCADA control. Systems fully comply with GAMP and cGMP standards.

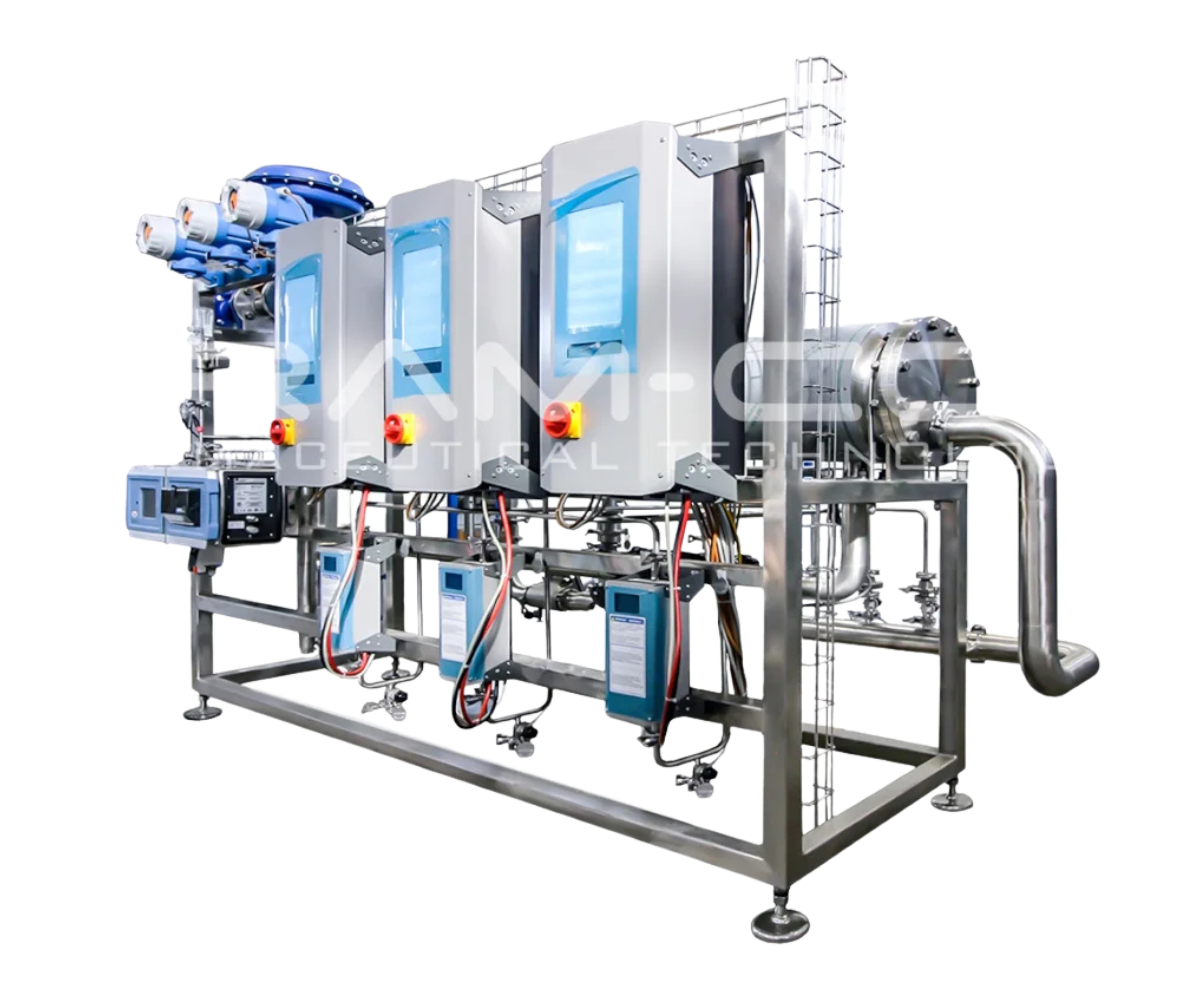

Formulation & Processing Plants

BRAM-COR designs and installs complete formulation and preparation plants, customized to each product and client requirement (URS). Our systems ensure sterile processing, easy cleaning, and full compliance with pharmaceutical standards—offering reliable and cost-effective solutions for aseptic production.

Main Equipment Includes:

✔️ Mixing Tanks, Pressure Vessels, and Bioreactors

✔️ CIP/SIP Cleaning and Sterilizing Systems

✔️ Ancillary Systems for Formulation Lines

Filling and Packaging Lines

✔️ Configurations for manual, semi-automatic, and automatic filling

✔️ Compatible with plastic or glass containers from 10 ml upward

✔️ Integrated solutions including washing, capping, and labeling

✔️ Designed for compliance, low maintenance, and durability