FORMULATION & PROCESSING PLANTS

End-to-End Solutions for Drug Formulation

Tailored Systems for Efficient and Sterile Pharmaceutical Production

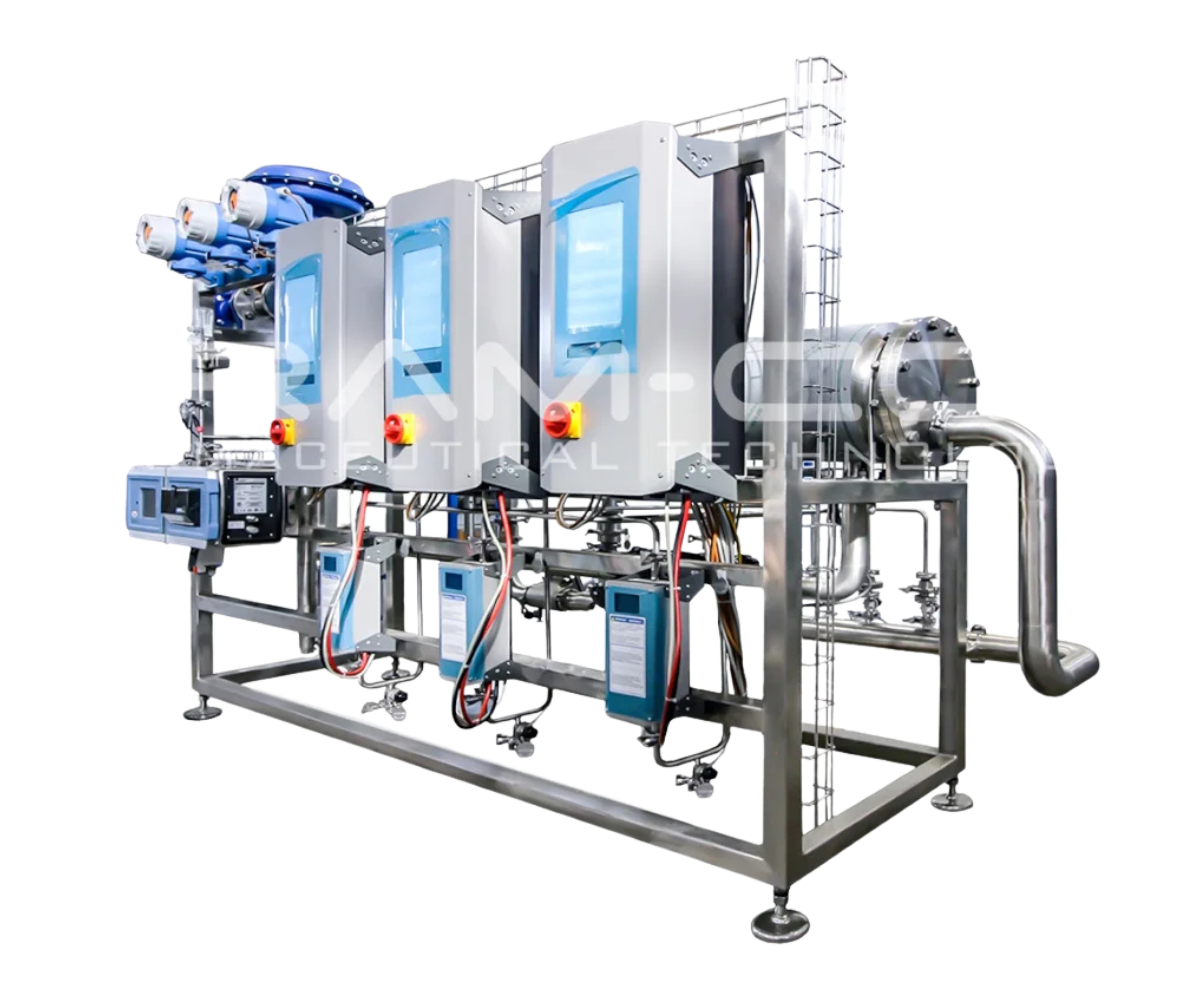

BRAM-COR designs, manufactures, and installs complete formulation and preparation plants based on specific product characteristics and client requirements (URS). Each project is carefully engineered to address key pharmaceutical challenges—especially the preparation, cleaning, and sterilization of all contact parts in tanks and systems, ensuring full compliance and aseptic integrity.

We deliver customized solutions to meet unique disinfection and sterilization needs, ensuring reliable, cost-effective performance. Our equipment is built for efficiency in aseptic processes, delivering lasting value and superior operational results across pharmaceutical manufacturing lines.

Mixing Tanks, Pressure Vessels and Bioreactors

- Mixing Vessels

- Pressure Tanks / Pressure Vessels

- Reactor Vessels

- Customized Formulation Tanks

- Mobile Mixing Vessels

- Transfer Tanks

Cip/Sip Systems

- Customized Clean in Place Stations

- Mobile Clean in Place Stations

Ancillary Systems For Formulation Lines

- Triblenders

- Filtration Groups

- Solution Transfer Circuits through

- Nitrogen Or Sanitary Pumps

- Vessels Loading Platforms

- Laminar Air Flow Cabinets

Other Equipment Categories

Water Treatment Systems & Lines

✔️ PW – Purified Water

✔️ WFI – Water for Injection

✔️ PS – Pure Steam

Our solutions cover every stage from supply water to final output, with advanced monitoring, material compliance (AISI 316L), certified gaskets, and automated SCADA control. Systems fully comply with GAMP and cGMP standards.

Filling and Packaging Lines

✔️ Configurations for manual, semi-automatic, and automatic filling

✔️ Compatible with plastic or glass containers from 10 ml upward

✔️ Integrated solutions including washing, capping, and labeling

✔️ Designed for compliance, low maintenance, and durability